BMW reveal 3D-printed S1000RR chassis

Is this the future of frames?

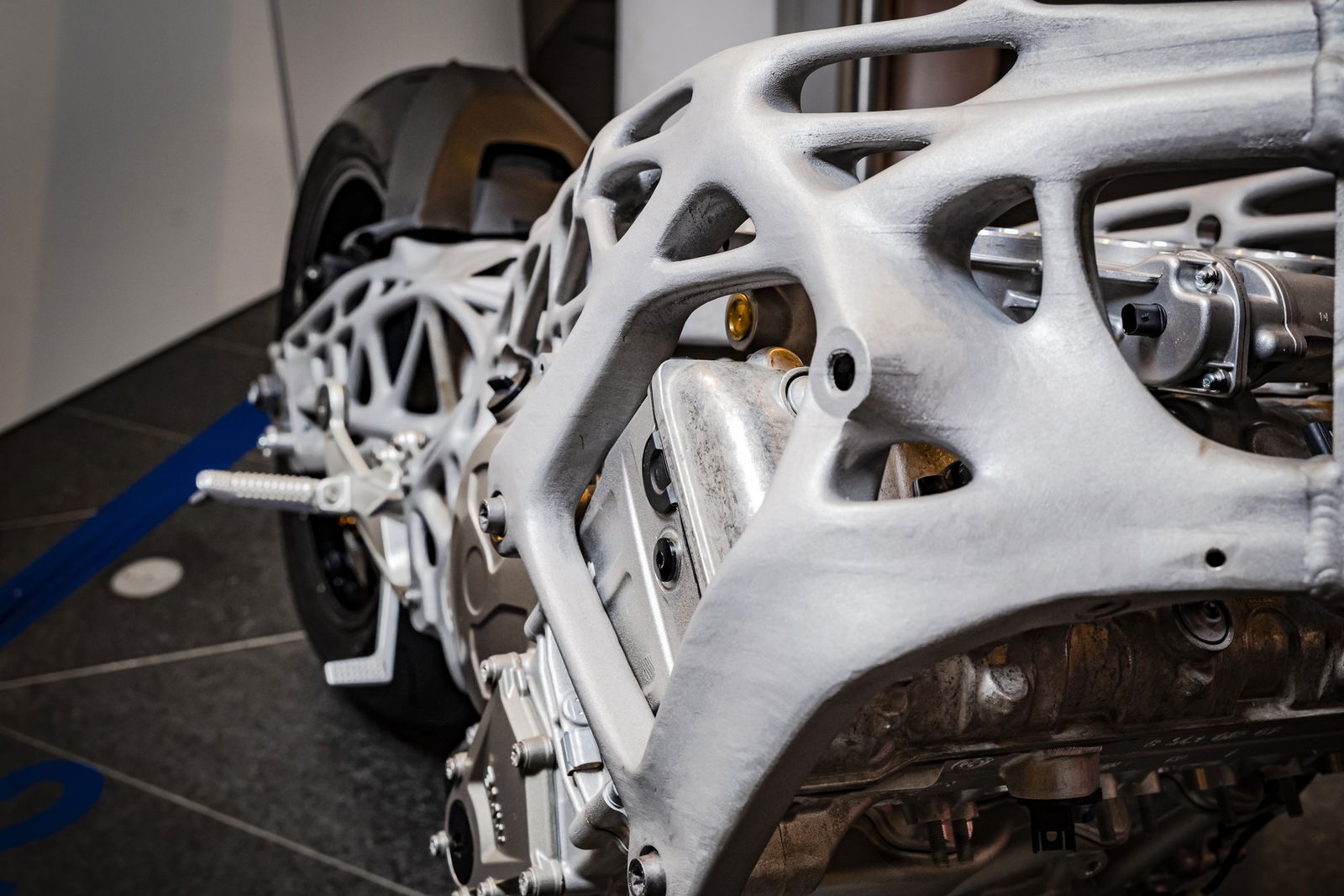

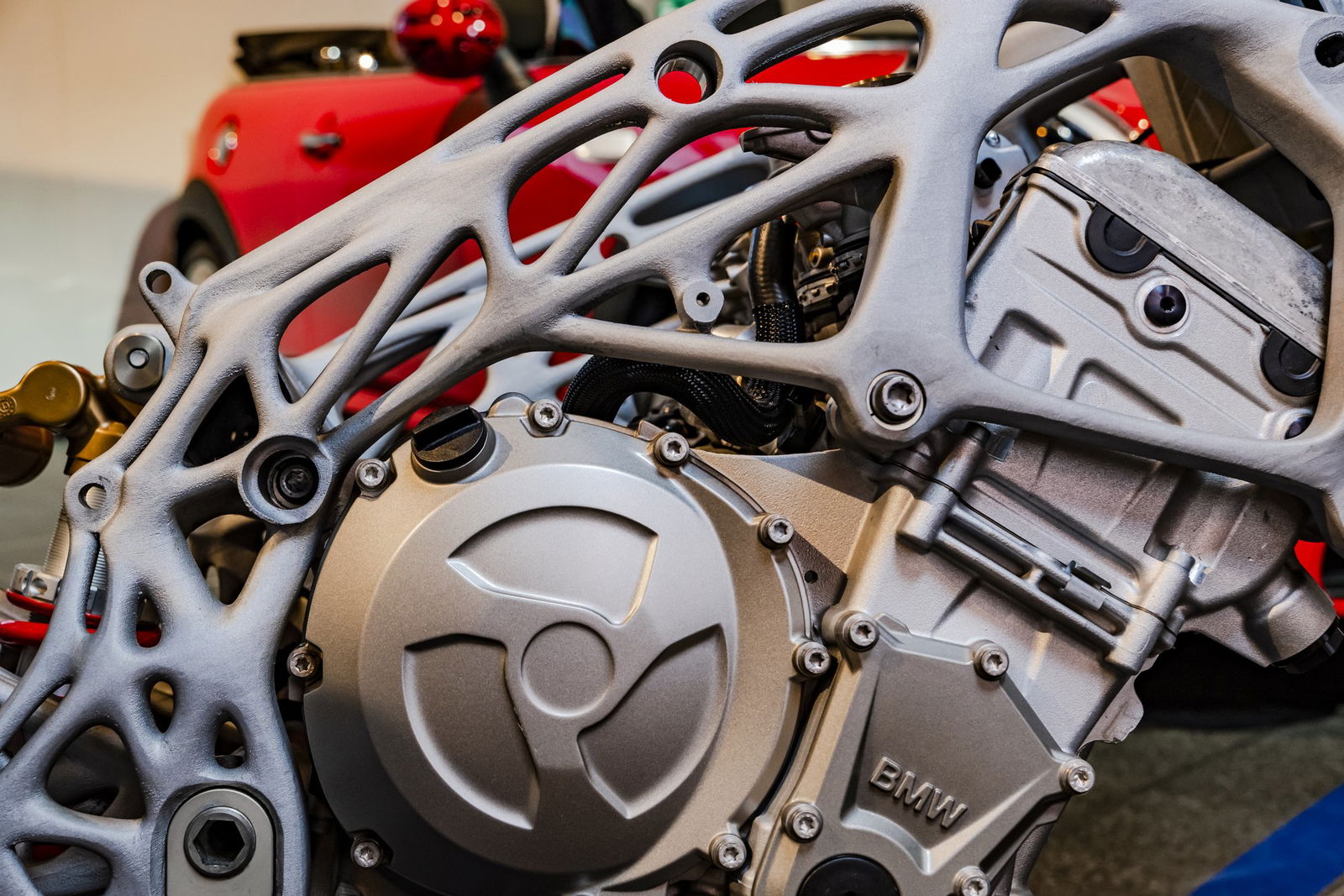

Just weeks ago BMW took a step towards mass-made carbon-fibre bike parts with a prototype cast-carbon swingarm. Now the firm is embracing another futuristic production technology and has revealed a completely 3D-printed S1000RR chassis and swingarm.

The part-built bike was revealed at the firm’s Digital Day in Mallorca, and regardless of any technical attributes there’s no question that it looks simply amazing. The almost organic way the frame and swingarm are built up makes the parts look like they’re from the set of Alien.

BMW hasn’t actually released a lot of information about the bike itself. It’s really just an example of what the company’s prototyping department is capable of creating, using 3D printing technology.

Calling the system ‘additive manufacturing’ BMW explains that: “three-dimensional parts made from plastic or metal take shape layer by layer. Additively manufactured parts offer a high degree of freedom in terms of their design, and they can be produced quickly and to the requisite quality. There is no need for traditional production tools such as press or casting moulds; the geometry of the parts is determined entirely by a digital dataset.”

At the moment, most 3D printed parts are used for prototypes rather than mass production, since they can be modified and remade very easily as designs are tweaked.

However, BMW also says there’s potential to use the technology in mass production. Some Rolls Royce car parts – RR being a BMW subsidiary – are already 3D printed. The firm says that the new BMW i8 Roadster also uses a similar technology, called metal powder laser melting, for the manufacturer of some components.

BMW also sees 3D printing as having a role in personalisation of its vehicles, saying: “Additive manufacturing is also playing an increasingly important role when it comes to customised vehicle parts. The new MINI Yours Customised product line enables customers to personalise the design of selected components, such as side scuttles and trim strips, and then have them produced by means of 3D printing.”

Don’t expect to waltz into a showroom and buy a complete 3D printed bike like this anytime soon, but you can be sure that the technology will have an increasingly noticeable effect on bikes in years to come.

.jpg?aspect_ratio=1:1)