Man Uses Hardware Shop Parts to Build Two-Stroke Engine

A Youtuber attempted to build a two-stroke engine from hardware shop parts, but was it successful?

Building a two-stroke engine will typically require a certain degree of expertise, experience, the right techniques and above all, the necessary equipment. However, Youtuber Camden Bowen has shown that building a two-stroke engine is also possible with persistence and a little thing called skill.

Despite owning a few tools needed to undergo this type of task, such as a lathe and welder, Bowen required much more than that as he went to different hardware shops in the hope of finding the right pieces to the puzzle. A hole saw set was one of those, which failed to fill the American with immediate confidence, but ultimately proved vital in constructing the engine.

Before I go further, how does a two-stroke engine work I hear you ask? So, get strapped in! Two-stroke engines are different from their four-stroke counterparts in three major ways. The first is that two-stroke engines do not have valves, thus simplifying the construction while also lowering the weight.

Secondly, two-stroke engines fire once every rotation, whereas a four-stroke is once every other rotation. This results in more of a power boost for the two-stroke. While two-stroke engines are typically found in smaller powered vehicles or machines, they can work in any orientation which gives it more flexibility. A four-stroke usually sits upright and can have issues distributing oil flow if it’s not.

Ok, back to how Bowen completed his two-stroke engine. After welding several individual parts, he then set about welding them all together, but issues began ramping up as chatter was coming from the cylinder. After writing out the measurements he needed to make this build successful, Bowen began constructing the crankshaft.

More welding later, and step-by-step the American Youtuber had a very nicely looking two-stroke engine, but it wasn’t starting as hoped for. The engine began to kick into a lovely pattern, but it was cutting out after all the starter fluid was burned off, and this was taking place within seconds.

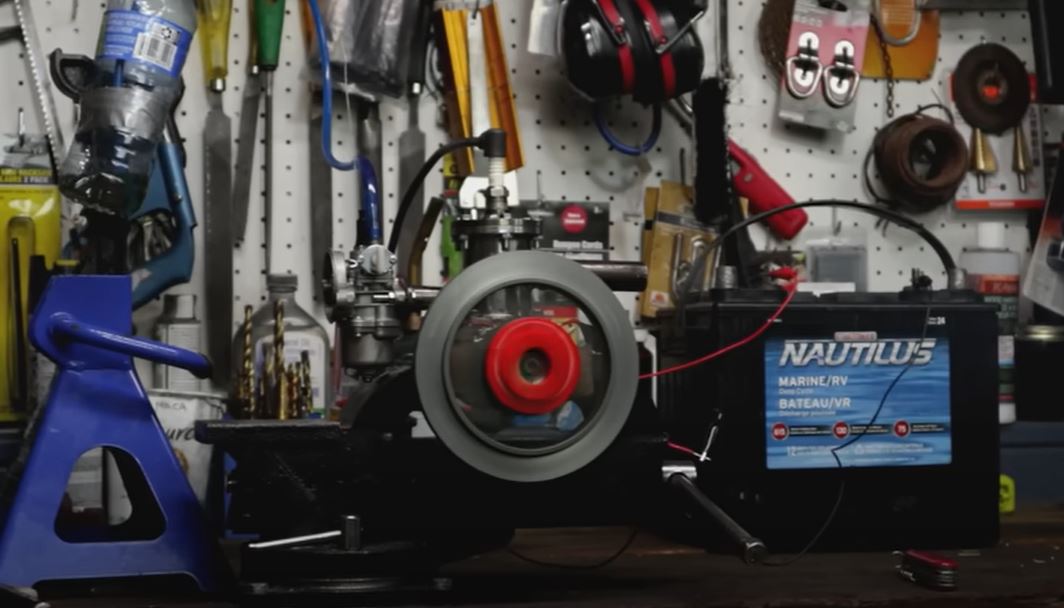

A project that took two months, Bowen finally got his two-stroke engine firing on all cylinders (excuse the pun) after applying oil to the crankshaft as his final job. Now, is this one of those YouTube tutorials that’s too good to be true? I’m here to say no!

(1)_0.jpg)