Moto 2 | How MV Agusta developed a competitive edge with aerodynamics

MV Agusta spent time in the wind tunnel refining the slipstreaming setup on their Moto2 motorcycle, in hopes to disadvantage their competition on track.

SINCE most of the spec in Moto 2 is kept strictly within the same confines, teams will be forced to seek to gain an advantage wherever possible. In this case, MV Agusta looked to develop a disadvantage for their competitors on track, to limit the amount of usable slipstream their bikes produce.

Given Moto 2 bikes all share the same Triumph triple 765cc motor with 140bhp and 217kg total weight (inc rider), the racing turns to each riders ability instead of the outright power of a machine, but teams will of course look to seek advantages wherever possible - even if that means creating disadvantages for the other riders on the track by reducing the useful slipstream provided by their bikes.

Watch | MV Agusta Brutale 800 RR Specs

In a brilliant article from racecar-engineering.com, Brian Gillen (R&D Director at MV Agusta):

“In a spec class where the powertrain, tyres and electronics are standard, aerodynamics can make the difference,”

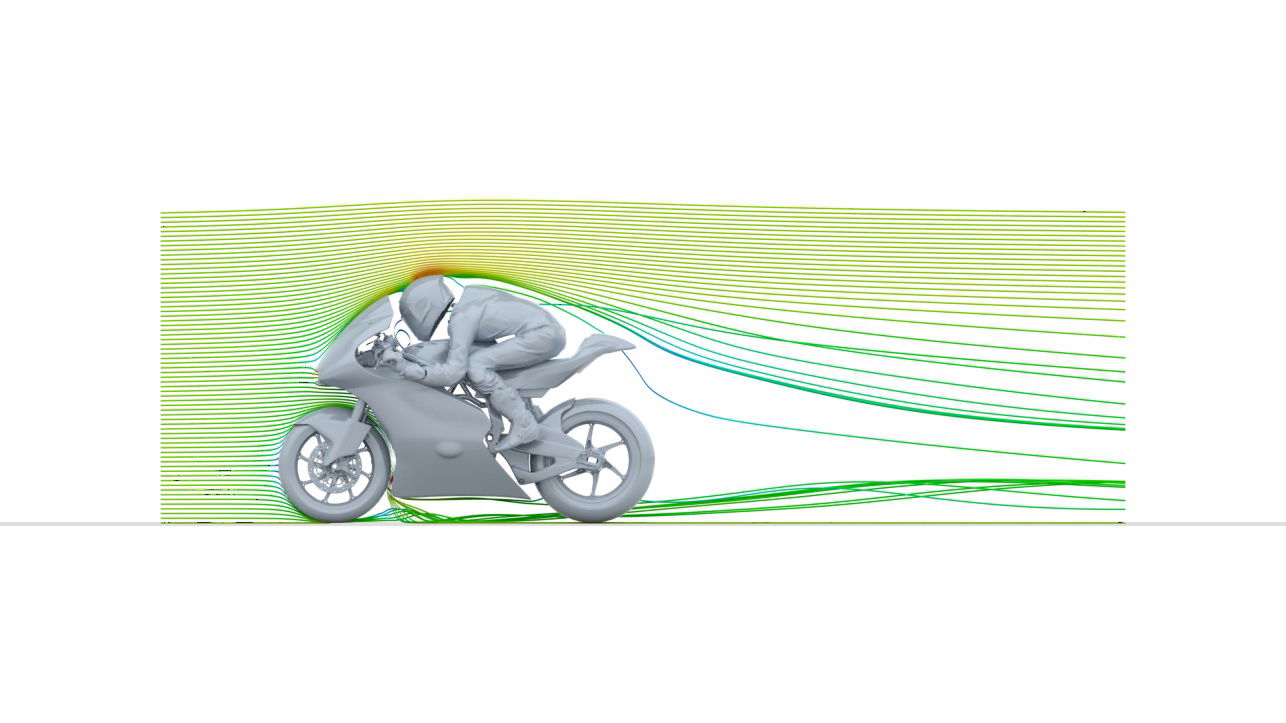

“Often, motorcycle aerodynamicists look to reduce the coefficient of drag as much as possible because they’re focused on top speed. However, the amount of time that you run on a racetrack at top speed, wide-open throttle and full rpm percentage-wise on a lap in Moto2 is minimal. Additionally, the gain in lap time as a function of top speed is limited as the bikes are so evenly matched.”

“Between the 2019 and 2020 versions of the bike, we spent a lot of time developing it to reduce the draft that we were giving to our competitors,

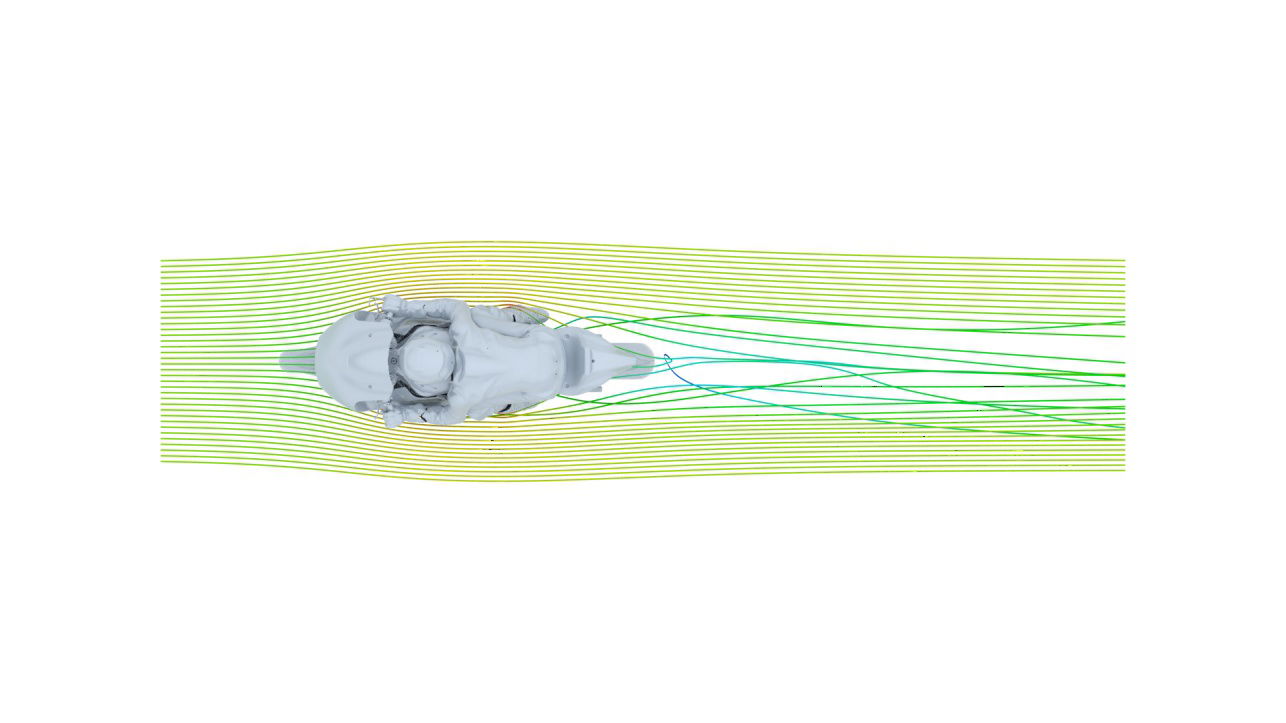

“We applied simulations that complement physical testing and match those two together. We were in contact with Airshaper to take a non-closed model and quickly put it through CFD algorithms to get back data to see what was possible to reduce the bike’s towing capability.”

“We then implemented different iterations of body shapes with a snapshot of where we were fluid-dynamically around the bike. Going into the virtual wind tunnel with Airshaper, we found out where we could make improvements."

"Being engineers, for us, data is nothing if it’s not validated. Having the possibility to do so using Airshaper aerodynamic analysis and the data that we had from the wind tunnel, we reached almost a total convergence.”

“On the track, this translated into an increase in the MV Agusta bike peak acceleration, increased stability and comfort for the rider and a reduction in closing in speeds from the other bikes as they were trying to catch a toe from our machine.”